Mkwawa Leaf Tobacco,a leading tobacco processor in Morogoro,Tanzania, sought to expand by adding cigarette packaging and increasing steam generation capacity. To meet growing demand, they partnered with Energy Partners’ Steam division to implement a more efficient and flexible combustion system.

The challenge

Mkwawa Leaf Tobacco was facing limitations with its existing boiler system, which could only produce a maximum of 10.5 tonnes of steam per hour, and was becoming increasingly unreliable. This issue resulted in frequent production downtimes and increased operational costs. Furthermore, the company needed a solution that could adapt to various fuel sources, given the fluctuating availability and costs of fuel in Tanzania. They needed a cutting-edge system that could improve both performance and efficiency while being environmentally friendly.

Project execution and success

Despite challenges, including material export issues and commissioning complications, Energy Partners Steam completed the project in 15 weeks — five weeks ahead of schedule. The new combustion system allowed Mkwawa Leaf Tobacco to operate its production line 24/7, with continuous and reliable steam supply.

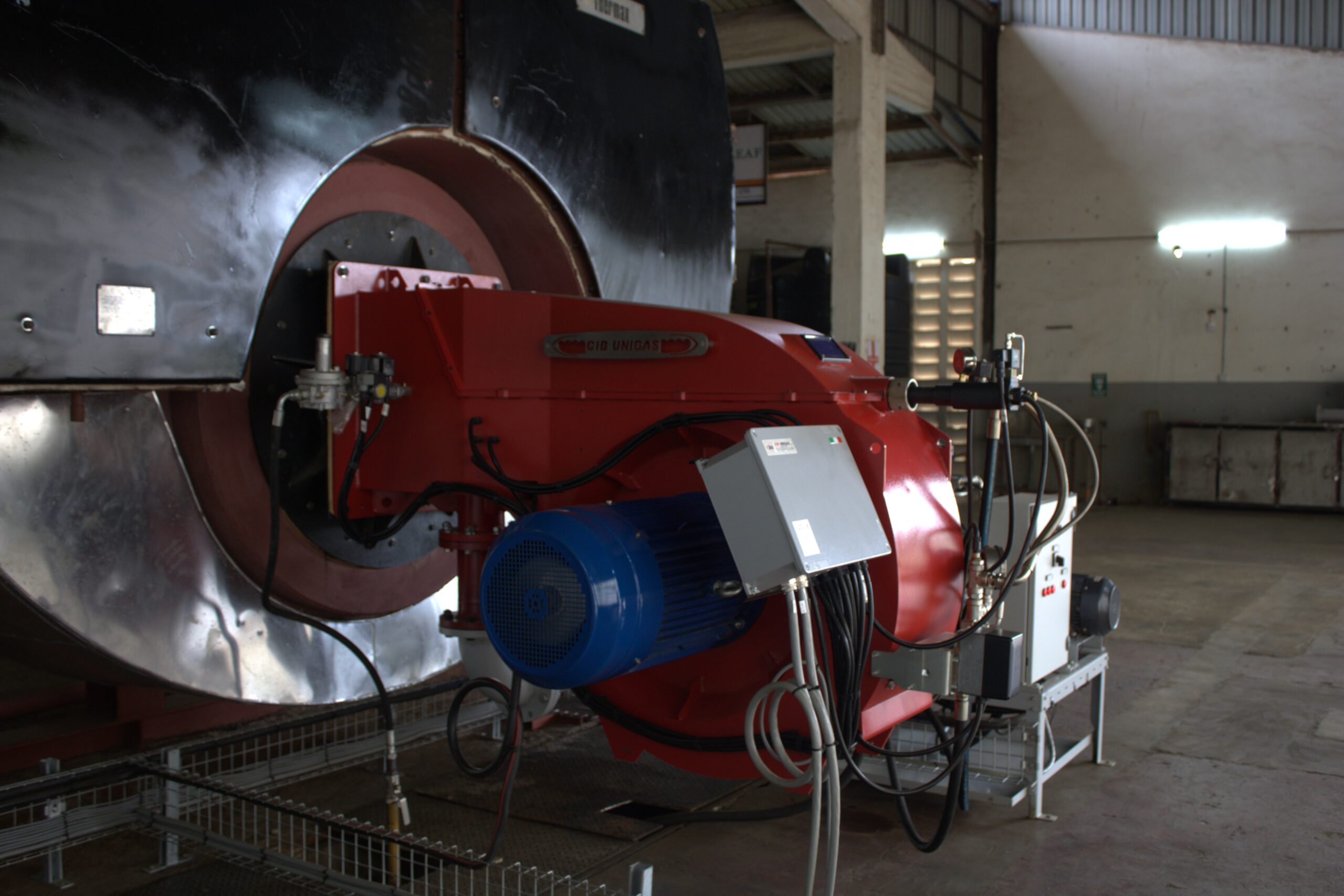

The solution: 4-fuel burner system

Energy Partners Steam provided a custom combustion solution with a 19MW Unigas burner, capable of running on multiple fuels, including Heavy Fuel Oil (HFO), Liquefied Petroleum Gas (LPG), Natural Gas, and a blend of Natural Gas and LPG. This flexibility ensured Mkwawa Leaf Tobacco could adapt to fluctuating fuel availability while maintaining cost efficien

Key features and benefits

Advanced control system

The system includes a precise control mechanism, enhancing combustion efficiency and extending equipment lifespan.

Improved boiler turn down ratio

With a turn down ratio of 1:10 compared to the industry’s 1:6, the burner reduces cycling and increases efficiency by up to 15%.

Optimised combustion performance

The system maintains:

O₂ levels below 6% and CO below 4ppm on HFO

O₂ below 3% and CO below 4ppm on gas fuels

These improvements increase fuel efficiency and cut costs.

Increased steam capacity

Steam production rose by 50%, reaching 16 tonnes per hour, ensuring uninterrupted operations.

Environmental and economic benefits

The system cut fuel consumption by 25%, lowering both operational costs and the company’s carbon footprint.

Financial impact and conclusion

Mkwawa Leaf Tobacco’s investment in Energy Partners 4-fuel burner system led to a 25% reduction in fuel costs, with a payback period of approximately one year.

This advanced combustion technology has revolutionised Mkwawa’s operations, increasing steam capacity, improving fuel efficiency, and reducing costs.

It has allowed the company to expand production while lowering its environmental footprint, highlighting the significant role of innovative technology in enhancing industrial processes and sustainability.