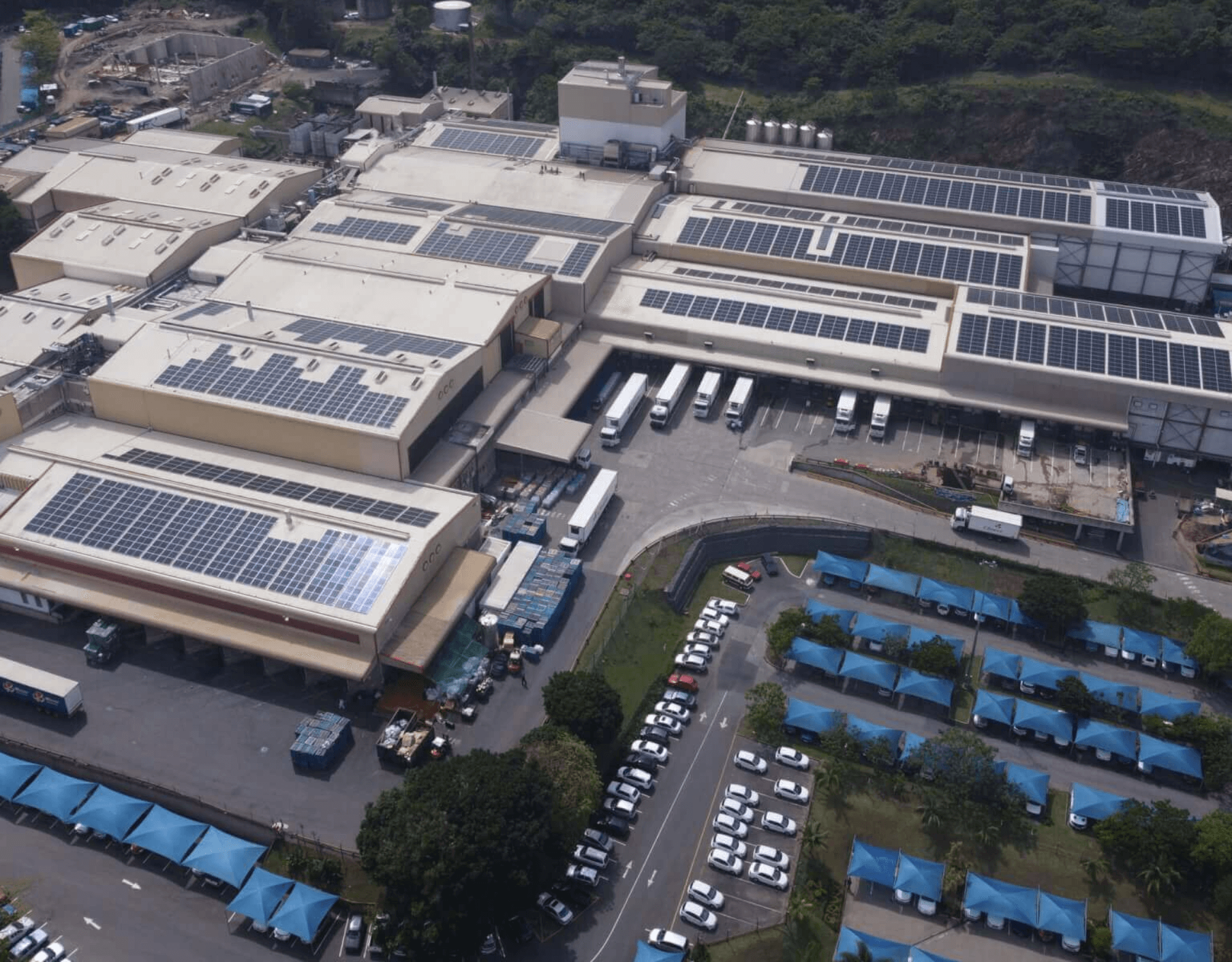

Clover – South Africa’s largest dairy company – is underway with a massive consolidation of their facilities as part of Project Sencillo, a program of projects focusing on the establishment of mega-factories, paying particular attention to reducing its energy consumption across the board and achieving overall improved operational efficiencies.

In this regard, Clover SA – with the support of service providers such as Energy Partners – is leading the way in terms of energy efficiency, showcasing some of the most impressive, outsourced models in the country.

Jonathan Probert, Head of Business Development for Energy Partners (EP) Steam explains, EP Steam is in the process of commissioning the three 25T/hr, 25 bar boilers. The installation includes water treatment, air-preheaters, economisers, and premium boiler combustion control systems, together with automated coal and ash handling plant, topped off with bag filters to comply with the stringent Durban emissions regulations – all designed in-house. “The installation is expected to go live in September 2022, and solidly establishes our footprint in KwaZulu-Natal.”

To this, Probert adds that the Clover Queensburgh project also stands out as one of the biggest outsourced steam contracts of its type in South Africa. “When combined with the outsourced contracts that this site has with EP Power and EP Refrigeration, the Clover Queensburgh project is one of sub-Saharan Africa’s biggest running outsourced contracts.”

He explains that the scope and requirements of this project have driven learnings that will make EP Steam one of the most competitive service providers in the game. “To start, the installation – which started in 2021 – took place during one of the most difficult times for this province in recent years. Throughout the COVID-19 lockdown, the floods and riots of the last two years, our team has perfected its ability to operate remotely and pull massive projects together in the most efficient way possible.”

Added to this, the system has been designed with future upgrades in mind. “The steam system accounts for current expected demand as well as an assumed annual growth over the next 20 years, and we have made provision for the expansion of the boiler house by 30% at a later stage.

All in all, Probert says that this unique EP Steam solution, designed specifically for Clover, perfectly demonstrates the capability that the energy specialist is able to achieve. “We are honoured to have been selected as their partner in a project of this scale, and it has helped us to gain an incredible foothold in the KZN region that will undoubtedly benefit many more businesses down the line,” he concludes.